In today’s fast-paced world, businesses across various industries require quick and efficient production processes to stay competitive. One crucial provider that addresses this need is speedy sheet steel fabrication. Whether it is for prototyping, complete-scale manufacturing, or custom tasks, fast sheet metal fabrication offers a streamlined technique to delivering remarkable steel components and merchandise in minimal time. This article delves into the importance of rapid sheet metal fabrication, its benefits, applications, and the factors to consider when choosing a service provider.

What is Rapid Sheet Metal Fabrication?

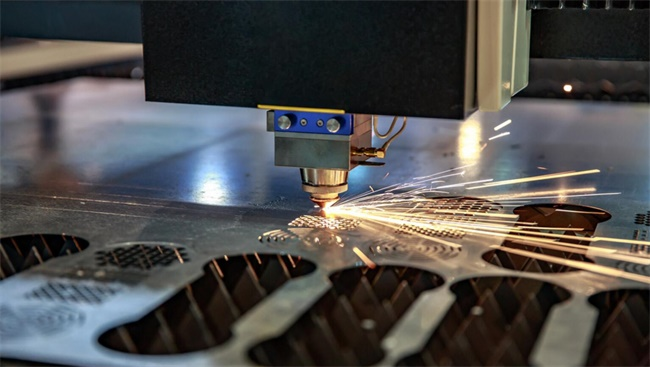

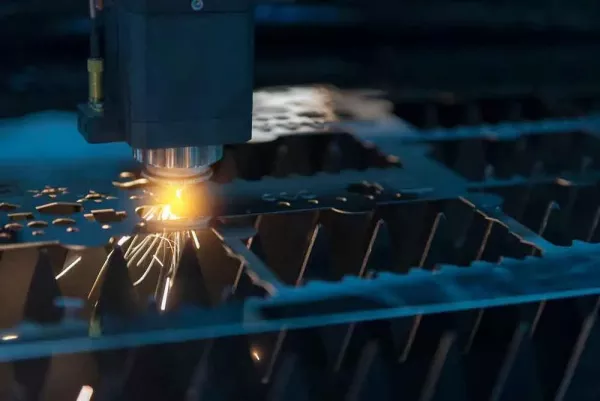

Rapid sheet metallic fabrication is a manufacturing process that includes the quick production of metallic parts the usage of strategies inclusive of reducing, bending, forming, and assembling. The time period “fast” refers back to the reduced turnaround time from design to manufacturing, which is made possible via advanced technologies like CNC machines, laser slicing, and automated bending structures.

Traditionally, the sheet metallic fabrication manner may want to take weeks, but with speedy fabrication strategies, lead times can be drastically shortened to simply days. This performance is important for industries that want to deliver merchandise to marketplace quickly or require frequent layout adjustments, including automotive, aerospace, customer electronics, and production.

Benefits of Rapid Sheet Metal Fabrication

There are several blessings to the usage of speedy sheet steel fabrication over traditional strategies, making it an more and more popular preference for manufacturers.

1. Faster Turnaround Times

One of the number one benefits of rapid sheet metallic fabrication is its ability to reduce production times appreciably. The aggregate of automatic machines and optimized workflows allows for quicker processing of uncooked materials, lowering the time needed to create parts. This is important for businesses running below tight cut-off dates or those seeking to expedite the product development method.

2. Cost Efficiency

Rapid fabrication reduces fees in numerous approaches. By shortening lead times, organizations can lower their exertions fees, lessen the want for time beyond regulation, and minimize delays of their manufacturing schedule. Moreover, because cutting-edge fabrication gadget is exceedingly specific, the amount of wasted material is significantly decreased, ensuing in lower fabric expenses.

For small-scale projects or prototypes, fast sheet metallic fabrication also can be extra cost-effective because it removes the need for high priced tooling or lengthy setup times, which might be common in traditional fabrication methods.

3. High Precision and Quality

Despite the rate of production, speedy sheet steel fabrication doesn’t compromise on first-class. In fact, using advanced era guarantees excessive tiers of precision and consistency. CNC machines and laser cutters, for instance, can reduce metallic to specific specs, minimizing the possibilities of errors or defects. This level of accuracy is crucial in industries wherein tight tolerances are required, including aerospace and scientific tool manufacturing.

4. Design Flexibility

Another big benefit of fast sheet metallic fabrication is the power it gives in terms of design. Because the procedure is so efficient, it permits companies to experiment with extraordinary designs or make adjustments to existing ones without lengthy delays. This is particularly beneficial for businesses inside the prototyping phase, wherein quick changes and refinements are important to obtain the precise layout.

5. Scalability

Rapid sheet steel fabrication is appropriate for each small-scale and big-scale manufacturing. Whether a organization wishes a unmarried prototype or hundreds of additives, the method may be scaled up or down fast to meet call for. This scalability makes it a great answer for companies seeking to develop or those that enjoy fluctuating production needs.

6. Reduced Time-to-Market

In competitive industries like electronics and automobile, getting a product to market quickly could make all of the difference. Rapid sheet metal fabrication helps corporations lessen their time-to-marketplace through dashing up the producing procedure, allowing them to release new merchandise faster and reply more efficiently to changing marketplace needs.

Applications of Rapid Sheet Metal Fabrication

Rapid sheet metallic fabrication has a extensive variety of packages across various industries. Some of the most commonplace programs include:

1. Prototyping

One of the most full-size makes use of of rapid sheet metal fabrication is inside the advent of prototypes. When growing a brand new product, companies regularly want to create several iterations of a layout before finalizing it. Rapid fabrication allows them to produce and check a couple of prototypes speedy, making sure that the final product meets all essential necessities.

2. Automotive Industry

In the car industry, rapid sheet steel fabrication is used to create custom elements, additives, and assemblies. From body panels to engine additives, the precision and velocity of the process are essential for retaining manufacturing timelines and ensuring the durability of components in demanding environments.

3. Aerospace Industry

The aerospace industry calls for fantastic, precision-engineered components made from light-weight but durable substances. Rapid sheet metallic fabrication lets in aerospace manufacturers to provide additives that meet strict regulatory requirements while maintaining manufacturing costs and timelines in test.

4. Medical Devices

In the clinical subject, wherein precision and high-quality are paramount, speedy sheet metal fabrication is used to create custom elements for clinical devices, surgical contraptions, and diagnostic gadget. The potential to quick produce prototypes and completed products is important for bringing new scientific technology to market.

5. Consumer Electronics

With the speedy evolution of patron electronics, manufacturers want to continuously innovate and launch new merchandise. Rapid sheet metallic fabrication enables them meet the demand for smaller, extra efficient additives without sacrificing pleasant or overall performance.

6. Construction Industry

The construction enterprise uses speedy sheet steel fabrication for creating metallic components utilized in constructing structures, HVAC structures, and roofing. The capability to supply custom components fast and as it should be allows creation organizations entire tasks on time and within finances.

Factors to Consider When Choosing a Rapid Sheet Metal Fabrication Service

If you’re in want of fast sheet metallic fabrication offerings, selecting the right company is essential for ensuring that your assignment is completed in your satisfaction. Here are a few elements to recollect when making your choice:

1. Technology and Equipment

The fine of speedy sheet metallic fabrication is largely determined through the era and device used. Look for a issuer that uses cutting-edge, today’s machinery which includes CNC machines, laser cutters, and automated bending equipment. These gear make sure precision and performance, decreasing the probability of errors.

2. Experience and Expertise

Experience subjects in terms of sheet metal fabrication. A organization with years of revel in is much more likely to supply awesome outcomes, specifically for complex projects. It’s also essential to don’t forget whether or not the business enterprise has know-how for your unique industry, as this will effect their ability to meet your requirements.

3. Lead Times

One of the number one motives to choose rapid sheet metallic fabrication is the velocity of manufacturing. Be positive to inquire about lead instances and pick out a provider that can meet your deadlines with out compromising on first-class.

4. Material Options

Different projects require one of a kind materials. Ensure that the sheet metal fabrication business enterprise you choose gives a variety of metal options, along with metallic, aluminum, copper, and brass, to suit your venture’s specific desires.

5. Customer Support and Communication

A desirable sheet metal fabrication employer have to provide brilliant customer support and maintain clean conversation for the duration of the system. This is especially vital for custom projects, where adjustments or adjustments can be wanted alongside the way.

Conclusion: The Future of Manufacturing with Rapid Sheet Metal Fabrication

Rapid sheet metal contractors is transforming industries with the aid of presenting quicker production instances, high precision, and design flexibility. Its advantages make it a really perfect solution for agencies seeking to innovate, streamline operations, and get merchandise to market quicker. Whether you are working on a prototype, a big-scale manufacturing run, or custom components, deciding on the proper sheet metal fabrication company will make certain that your project is completed effectively and to the best requirements.

More Stories

Site Oficial Para Cassino Online E Apostas No Brasil

Site Oficial Para Cassino Online E Apostas No Brasil

Site Oficial Sobre Cassino Online At The Apostas No Brasil